Professional Experience

Zipline

Mechanical Test Engineer — System Prototype & Test

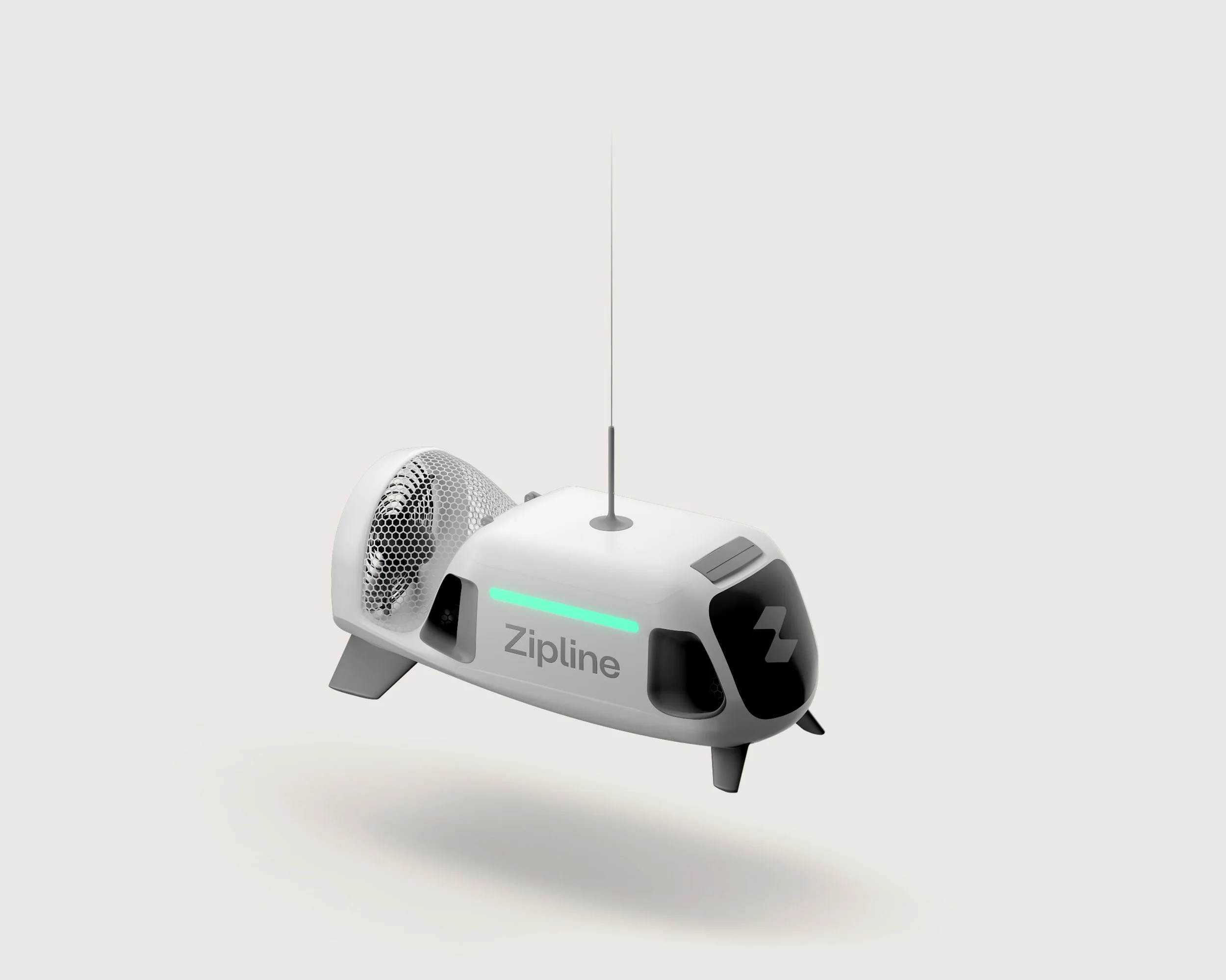

P2 Prototype Droid — Design, Integration, Test, Build

Prototype Testing at Zipline Overview:

Developing a prototype aircraft to identify & test the highest-risk aspects of the product before hardware designs are finalized, ensuring future functionality

Designing new versions of the prototype vehicle to integrate final designs as they are released

Owned all mechanical aspects of the latest iteration of the P2 Prototype Droid, including build, maintenance, hardware components, and root causing of flight failures encountered during testing

Led hardware integration efforts between the prototype delivery drone (Droid) and flying drone (Zip)

Designed mounts to hold electronic components inside the Droid

Testing the P2 Prototype Droid in mock backyardsWinch System — Design, Build

The Winch is the system in the Zip that drops the Droid from the sky to the ground for deliveries

Redesigned the latest revision of the Winch system for prototype Droid testing with integrated electronics hardware, allowing for isolated testing of the Droid independent from the Zip

Built two Winches for prototype Droid testing, ensuring compatibility with the prototype Droid as well as future Droids (non-prototype vehicles)

Data Collection Mount

Needed to instrument a Zip with cables & sensors for various in-flight measurements, which required the data acquisition unit (DAQ) to be attached during flight without causing additional vibrations that could skew data collection

Designed a mount for the DAQ to maximize structure & stiffness while minimizing mass

Heat Insert Installation Tool

The build instructions for a Zip required installing heat inserts into the servo bosses on the wings & tails of the aircraft, an unreliable method that causes inconsistency & variability during builds.

Designed a tool to streamline the insertion process in three specific areas:

(1) control the angle of heat insert during installation,

(2) constrict the servo bosses when heat is applied to prevent expansion or bowing out,

(3) ensure the tool is flush with the top of the bosses for easy visual inspection.

Collaborated closely alongside engineers and technicians to iterate upon the tool, determining specific tolerances, ensuring the tool works as intended, and selecting the ideal material.

ICU Medical

Systems Verification Engineering Intern

Developed R&D test methods and equipment to support formal verification of next-generation infusion pumps

Assembled and qualified six backpressure-inducing vessels to challenge fluid delivery accuracy by simulating intravenous pressure

Optimized verification methods by selecting a specialized low flow rate sensor and designing innovative accuracy tests

Authored and executed a qualification strategy for a 6-axis robot used for accelerated life testing

Navigated an FDA-regulated quality system to write and release verification protocols & reports